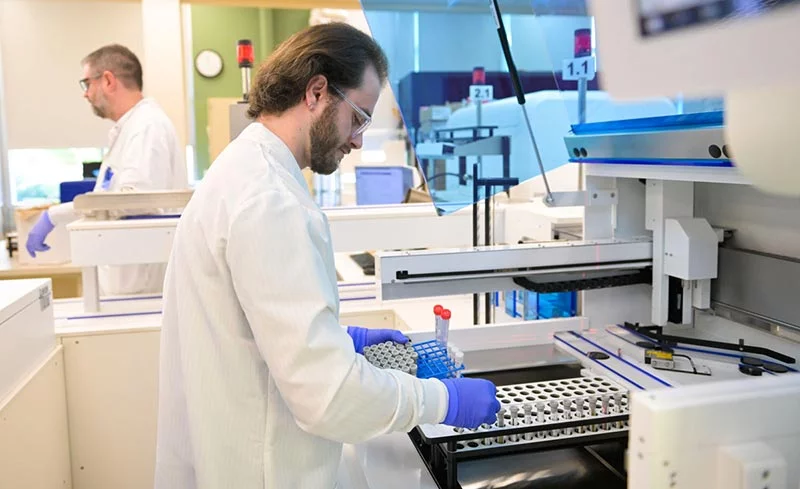

The microbiology team at the UCHealth University of Colorado Hospital Clinical Laboratory on the Anschutz Medical Campus has always been a hard-working group, and they have had to be.

Each day, about 650 patient samples of blood, urine, and other bodily fluids arrive via pneumatic tube and dumbwaiter from all corners of University of Colorado Hospital along with satellite hospitals and clinics. A high-stakes, multi-step process ensues to help doctors identify what is causing illness and to suggest doses of the antibiotics, antifungals, and other treatments that help patients beat what could otherwise be life-threatening infections.

For decades, it’s been a manual process. Now there’s Kiestra.

Kiestra is a sleek microbiology lab automation system made by New Jersey-based BD. Its arrival in July 2022 was timely. Demand for the microbiology lab’s expertise has grown about 10% a year for more than a decade, with no end in sight, says Veronica Broslawik, the lab’s manager.

The recently opened new inpatient tower will add 215 beds to the 678 in University of Colorado’s existing two inpatient towers when fully staffed next year. Plus there’s an ongoing national shortage of microbiology-lab talent.

UCHealth’s roughly $3 million investment in Kiestra is already paying dividends, Broslawik says.

“Microbiology is in its renaissance era, or its industrial revolution,” she says. “We’re able to leverage these technologies that were never applied to the field.”

The workflow in a microbiology lab

The microbiology laboratory’s pre-renaissance workflow went roughly as follows. Samples arrived in test tubes. Microbiology staff gave each sample a quick look under the microscope to see if there were obvious infections. If so, they can let the doctor know whether it looks like Serratia marcescens or Pseudomonas aeruginosa or Escherichia coli or one of many other unwelcome bodily invaders. But that was just triage.

Some test tubes got incubated in what looked like six big refrigerators but in fact, are kept at 98.6 degrees – body temperature. Others got hand-pipetted onto agar plates seeded with growth media. Assuming they were bacterial or yeast (fungi, less common, took a different path) the agar plates were hand-carried to a different incubator, where they would spend the next 18 to 24 hours letting the bugs multiply.

The agar plates then landed in tall stacks on the desks of microbiology lab experts, who inspected them with microscopes and made their calls as far as what was happening – if anything was happening – on the plates and what a doctor should consider prescribing to counter it.

Some samples headed to a Bruker MALDI-TOF mass spectrometer that could identify microbes by determining how light bounces off their many proteins. These results would also be shared with doctors on the floors.

New technology in UCHealth’s microbiology lab

With Kiestra, the processes are mostly the same. They’re just more automated. Kiestra does the pipetting into the agar plates for most samples. Via blue conveyors, it sends the plates to a 0Kiestra ReadA Compact intelligent incubation and imaging system. This is a closed-loop system that first incubates, then takes up to 22 photographs at 25 megapixels each, creating highly detailed composite images that microbiologists then inspect on a screen, panning and zooming as they please.

That closed-loop matters, Broslawik says. The unavoidable, constant opening and closing of incubator doors drops the temperature and slows microbial growth. Kiestra cuts incubation time by six to eight hours.

“We’ve reduced the time our patients are waiting for the results a lot,” Broslawik says.

The MALDI-TOF is still identifying its microbes, but it’s been joined by a Kiestra module that can test different antibiotics and antibiotic doses in samples to see what kills the microbes – known in the business as “susceptibility.” That combination of speed and better information in the physician’s hands “absolutely can be a life-saver,” Broslawik says.

‘Amazing’ technologies and lab automation

Members of the 43-person microbiology lab team are fans of the new system. Liz Kassner, a microbiology lab supervisor in her 43rd year in the lab, says change happens in the field, and it has been for the better.

“The technology that’s come about in the last few years has just been amazing,” she says. “Kiestra fits right into that.”

The automation lets her focus on what she views as her primary role: to use her skills and long experience to teach others the nuances of identifying what are often rare bugs.

“Our patients are very, very complicated. The kinds of organisms we isolate are unusual,” Kassner says. “You wouldn’t see these kinds of organisms in a community hospital”

Emilie Predota, a microbiology lab supervisor who has been with the lab for nine years, changes the brightness of a sample from a urine culture Kiestra had sent to her screen, zooms in, and marks bacterial colonies with a click-click-click. There’s not an agar plate to be seen on her desk.

“I think it’s made us more efficient in getting doctors their results,” Predota says.

Michael Scheu, a lead Medical Laboratory scientist, says Kiestra is improving consistency and efficiency while enabling the lab to do more with less.

“I think people fear that anytime the word ‘automation’ comes up, they’re going to be out of a job,” Scheu says. “But the truth of the matter is, we’re opening a third tower. Our workload is not decreasing. We need assistance for all of us to do the work that we do.”

Broslawik agrees.

“It takes the low-value-added things out so we can focus on the things we train to do as microbiologists,” she says.